Approval of suppliers

Supplier certification is a key process to ensure that a company only works with partners that meet the quality, safety and accountability requirements of their industry. More and more organisations are digitising this procedure to reduce risk, gain efficiency and ensure regulatory compliance.

What is the supplier accreditation?

The supplier accreditation is a key process to ensure that a company works with partners that meet the standards of quality, legality and accountability required in their sector.

It consists of evaluating and approving suppliers, The first is that they must offer high quality products or services to maintain the company's standards. First, they must offer high quality products or services to maintain the company's standards.

Another fundamental aspect is verify technical and sectoral certifications, as the ISO, The supplier must have the necessary skills. Occupational health and safety is also crucial, especially in high-risk sectors. Finally, sustainability and social responsibility are increasingly relevant, as companies seek partners who respect the environment and follow ethical practices.

The supplier approval process helps to ensure business continuity.

Why is it important to supplier accreditation?

Working with non-approved suppliers poses direct risks. The main benefits of an accreditation system include:

Legal and regulatory compliance.

Reduction of risks and errors.

Improving the quality of goods and services.

Stronger corporate reputation.

Efficiency in management thanks to digitalisation.

Many companies still rely on spreadsheets or email exchanges to carry out supplier validation. This system, although common, has significant limitations: information is scattered and not centrally controlled, which delays validation and increases the risk of errors or data loss. In addition, when the time comes for an audit, the process becomes complicated, time-consuming and inefficient.

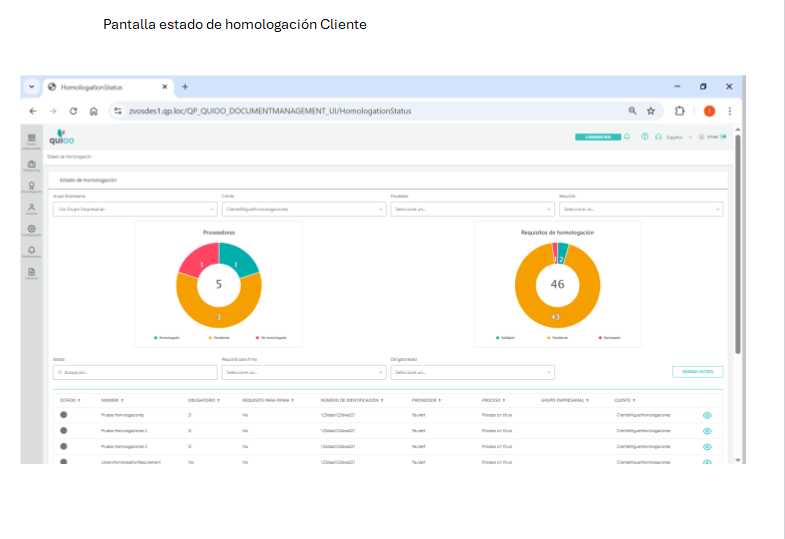

Advantages of digitising with Quioo

Digitisation is not just about convenience, it is about security and efficiency. Software such as Quioo contributes:

- Centralisation: all documentation in a single system.

- Time and cost savings: automated flows that eliminate manual tasks.

- Better relations with suppliers: agile and transparent platform.

- Security and traceability: record of all actions, useful in audits.

- Scalability and customisation: adaptable to different categories and regulations.

Cases in which it is essential

Supplier certification is key in a variety of contexts where efficiency, compliance and sustainability are essential.

Companies with high supplier turnover

In sectors where companies work with a large number of different suppliers, certification is crucial to ensure that all suppliers meet quality and safety standards.

Regulated sectors

In sectors where specific regulation exists, non-compliance can have serious consequences.

Multinationals

Large companies with international operations require a unified approval system to ensure that suppliers in all countries meet similar criteria.

Implementation of a digital system

The implementation of a supplier approval software is an essential process to optimise management and ensure compliance with the requirements of the quality standards, safety, environment, data protection, information security, etc. Through proper planning and adaptation, companies can digitise this process, increasing efficiency and reducing operational risks.

Initial diagnosis

The first step is to conduct a thorough diagnosis of the current situation of the company. This includes analysing existing risks and detecting points for improvement in the approval processes. A clear diagnosis will identify the areas that can benefit from digitisation and optimisation, ensuring that the implemented software meets the real needs of the organisation.

Definition of criteria

Once the diagnosis has been made, it is crucial to define the criteria to be used to evaluate suppliers. This should cover both legal and regulatory requirements of the sector as well as internal technical and strategic criteria. These criteria will help to establish the basis for supplier accreditation, ensuring that all partners meet the expected standards.

Software configuration

The next step is to configure the software to perfectly fit the needs of the company. This involves customising the system according to the categories of suppliers being managed and the internal approval and validation flows. The correct configuration of the software ensures that the process is streamlined, efficient and meets the organisation's specific requirements.

Communication with suppliers

It is essential to maintain fluid and clear communication with suppliers throughout the process. Be sure to explain the advantages of the new digital system and resolve any doubts they may have. Proper integration of suppliers into the approval system facilitates the uploading of documentation and the fulfilment of requirements, improving the relationship and collaboration between both parties.

Monitoring and optimisation

Once the software is implemented, continuous monitoring of the system is necessary. This includes reviewing established KPIs, adjusting approval criteria as necessary and optimising processes as the company grows and faces new challenges. Constant optimisation ensures that the system remains up-to-date and efficient, adapting to regulatory or market changes.

Approving suppliers is protect your business

Approving suppliers is not a formality, it is a guarantee of quality, compliance and trust. Managing it manually is risky; with specialised software such as Quioo, The process becomes digital, secure and traceable.

Do you want to take your company's supplier certification to the next level?

Find out how our supplier certification module Quioo can help you manage this process more efficiently and safely.

The experience of users